Scientists Learn How to Turn Electronic Wastes Into Nanodusts

We have reported that electronic wastes or e-wastes in Asia have significantly increased to 63% within the past decade. That percentage accounts to a total of 12.3 million tonnes of discarded electronics. But note that the number only reflects that of Asia’s Electronic Wastes – recent estimates say that the piles will reach 50 million tonnes worldwide next year.

Scientists never took this situation sitting down and finally arrived with a solution to the Electronic Wastes problem: recycle the discarded electronics by pulverizing them into nanodust.

Far from the conventional e-waste treatment that is just dumping into landfills or recovering metals and alloys via incineration and chemical treatments, this solution is a more efficient and environmentally friendly way of breaking down the e-wastes. Not to mention more economical.

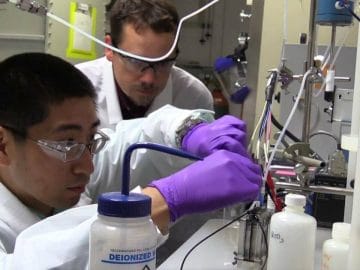

Chandra Sekhar Tiwary, a materials engineer from Rice University in Texas and the Indian Institute of Science, says that the cycle of e-wastes is but one way, with burning or using chemicals taking a lot of energy while still leaving waste.

The suggestion revolves around a grinder called cryo-mill that turns the e-wastes into ultra-fine particles that can be repurposed. It makes use of a freezing chamber to prevent heat-sensitive materials from melting together as they’re ground up.

During tests, two circuit boards from a computer mouse were milled by engineers in the cryo-mill at extremely cold temperatures – about -119 degrees Celsius. That’s with the help of the liquid nitrogen inside the cooling chamber.

To pulverize, the cryo-mill grinding chamber has argon gas and a small steel balls that is agitated. The product? Nanoparticles measuring between 20 and 100 nanometers wide that do not contaminate each other.

In case you can’t imagine the size, just compare it with the width of hair which is at 80,000 to 100,000 nanometers.

Tiwary said that the system breaks all of the components, including metals, oxides and polymers, into homogeneous powders and makes them easy to reuse. “Nothing is wasted,” she added.

For now this has been done on a small scale. But given that it was achieved, it’s not impossible that this solution will soon empty the e-waste landfills.

Source: Science Alert