Every Caterpillar, Komatsu, Case, Volvo, and Deere equipment in use at construction sites today are products of a careful developmental study in manufacturing. Ever since industrialization began, builders and engineers sought for advanced construction equipment and machines that will render smooth site operations at minimum costs.

Today, we have all the basic construction equipment we need. Using excavators, backhoes, loaders, cranes, and rollers, among others we have formed and built engineering marvels. Engineers always find a way to maximize the use of these equipment.

And yet, we could take advantage of modern technology to further exploit the use of these equipment, and to develop more machines that will help in forwarding construction methods.

There are essentially three areas which are the focus of construction equipment manufacturers in relating its past, present, and future. Once these three – hydraulics, engines, and computer systems – are engineered to be better than its current state, they lead to lower maintenance costs, decreased operation costs, improved efficiency and reliability, and longer machine life.

Source: Caterpillar Twitter

Excavators, backhoes, and loaders have hydraulics embedded in them to lift, load and unload materials and objects. Mobility of these equipment relies in this system. What emerging hydraulic technologies can do is optimize both hydraulic flow and pressure, including the ability to modulate both. They will largely affect the equipment’s efficiency, versatility, and lifting capabilities.

There are still so much to forward with engine controls, fuel injection systems, and the engine combustion process. When engineers work to improve these areas about the engines in construction equipment, it will yield increased fuel efficiency and decreased amount of harmful emissions into the air. The greatest impact in redesigning the engine is in the environment, being a critical issue in the construction equipment industry.

Computer systems are only a recent integration with construction equipment, but they make waves for enhanced site performance. Digitization, including GPS navigation, allows more effective monitoring in machine operations, more analyzed fuel efficiency, much controlled hydraulics, and reliable reporting of machine performance – all of which are in the end part of the construction process.

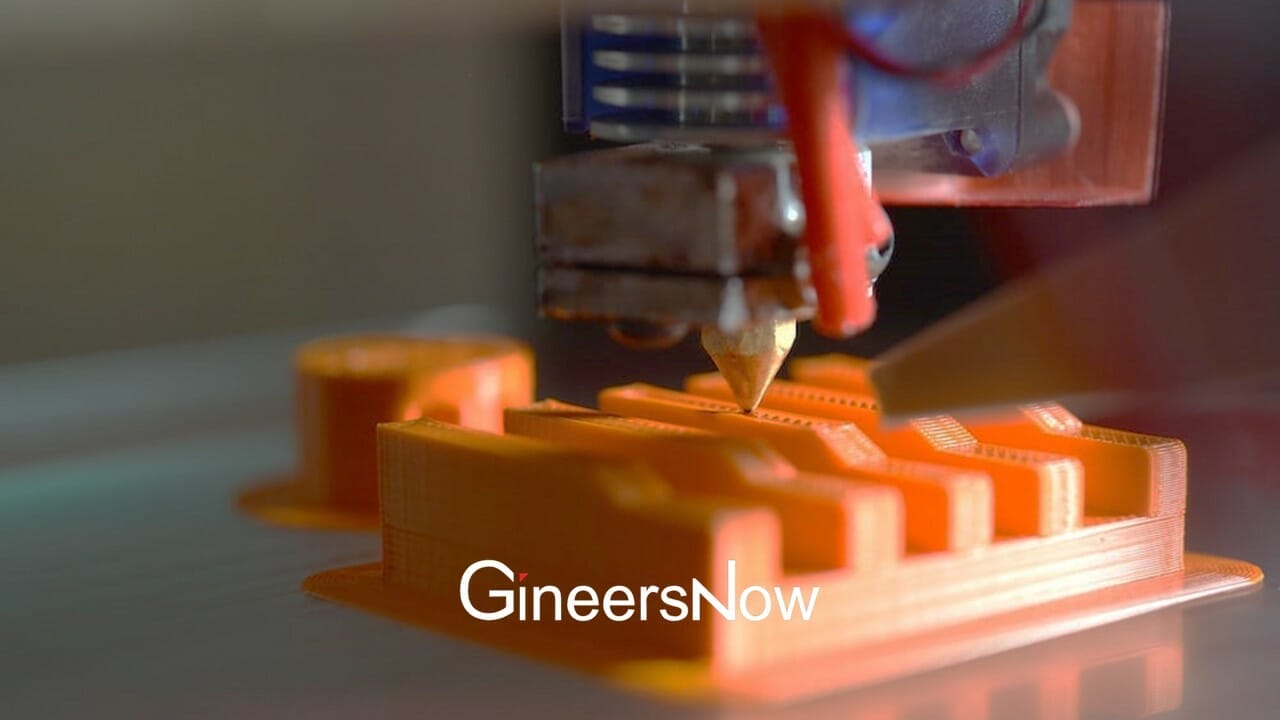

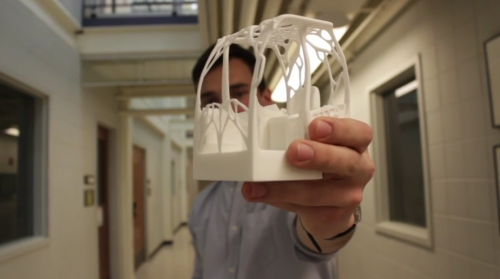

While these three are existing areas that seek improvement, there is also a room for creativity in the manufacture of construction equipment by producing hybrids and using 3D printing.

Source: Komatsu Twitter

There are already existing hybrid excavators and hybrid bulldozers, which will continue to flourish as manufacturers look in this area to accelerate site operations.

Source: Construction Equipment

But there’s a more current technology, the 3D printing or additive manufacturing, which takes production of construction equipment to an entirely new level. It allows modelling of equipment parts like cabs, booms, and buckets, as 3D printing provide design allowances not found in conventional manufacturing.

Efficiency, quality, and safety are the cores of construction equipment. And they remain to be so in the future, just catching up with modern technology.