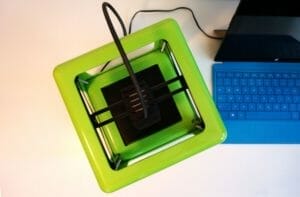

3D printing is one of the most significant advancements in the field of technology. We can see this process being used in different industries— medical, automotive, toys, manufacturing, and many others. With this kind of tech, creativity is the only limitation to what can be produced. Unfortunately, many 3D printers are pricey and therefore, not everyone can easily afford it.

That’s why Michael Armani and his business partner David Jones founded a company in 2013 wherein they developed the Micro 3D Printer, which is ultra-affordable, portable, and gives high quality results. This printer is ideal for artists, engineers, students, and hobbyists alike.

GineersNow conducted an exclusive interview with Michael Armani, the co-founder and president of M3D.

THE COMPANY

GN: Tell us about your company. Describe your mission, vision, and values as well as your strategic goals.

Armani: M3D is a private company with 50 employees, headquartered in Fulton, MD. We made a splash with our Kickstarter campaign for the Micro in 2014, which broke crowdfunding records. Our main company mission is to take complex technologies, innovate them, with the goal to lessen the barrier to entry for mainstream consumers. We decided to first tackle 3D printing, launching the Micro 3D Printer in 2014 and currently developing a more advanced model, the M3D Pro. Our current track right now is to continue innovating the 3D printer space with a focus on design, accessibility and reliability.

INTRODUCTION

GN: What is your company’s opinion on today’s consumer electronics/computer/IT technology?

Armani: The emergence of accessible technology makes it an exciting time to be in the consumer tech space. Lots of companies, including M3D, are finding ways to break down complex technologies for everyday consumer use, delivering them at a cost that won’t break the bank. Most developing countries, however, especially for everyday citizens, don’t have access to today’s forward-thinking consumer electronics simply because they can’t afford it, focusing on other financial priorities. These products can deliver life changing results, it’s just a matter of innovating the supply chain in order to reduce costs for greater access across the world.

THE MACRO LEVEL OF THE WORLD’S CONSUMER ELECTRONICS TECHNOLOGY

GN: Where are we today? What is the current situation of the Consumer Electronics technology locally?

Armani: Whether it’s in the form of wearables, chat bots or autonomous cars, technology has made its entrance into nearly every sector. We’re a world built on technology— it’s modern day magic. And as these technologies become further advanced and the development process sees further innovation and progress, they’ll become more functional and widely accessible over the next 20 years. Costs generally decrease over time as efficiency increases for consumer electronics—and I think we’re well on our way, with our own products as a strong example. Consumer 3D printers today already hover around the $1000+ mark, and we deliver ours at the fraction of the prize without a loss in quality.

THE MICRO LEVEL

GN: What are the initiatives / projects that you are doing (or have done) that will provide these advanced technologies to the public?

Armani: M3D believes that 3D printing is one of the most important innovations in recent years, so we’re doing our part to make it widely available with affordable and easily-operated printers. It’s clear that the public is ready for this kind of technology as evident in both of our Kickstarter campaigns. We’ve launched two, (one for the Micro and Pro) and they have been met with incredible support from consumers of all backgrounds.

GN: What impact have you delivered (social, economic and environmental)?

Armani: Besides widening the pool of people that 3D printing can reach, M3D is working with a number of local organizations to widen the technology’s reach.

For instance, we work with YouthQuest, a non-profit that supports the academic, vocational and life-enriching development of America’s youth. 3D printers can add a hands-on and visual element to learning, especially for STEM subjects. 3D printing models can “simplify” and serve as a strong entry point for STEM fields and spur long-lasting interest in them. Occupations in these related industries are steadily growing each year, making it absolutely worthwhile to make this kind of small investment in the classroom – it’s an investment in all of our futures, really.

THE CHALLENGES & SOLUTIONS

GN: What are the greatest challenges in the CE industry?

Armani: One of the greatest challenges for companies in this industry is keeping up with the quick product cycles and intricate international supply-chains. The companies that are equipped to adapt to varying international standards are more likely to succeed. Everything from raw materials to labor costs can act as enormous barriers to getting a business off the ground. The best way to lessen the impact of these challenges, and therefore encourage innovation, is to reduce and stabilize the costs involved in production— which can be accomplished by manufacturing entirely in-house. Our production facility is right next door to our headquarters and everything is built entirely in the United States. This degree of proximity allows us to aptly monitor the quality of our printers and quickly implement changes in the manufacturing process.

That said, again, the number one challenge of getting consumer electronics to people all over the world is cost. The consumer-facing prices of these devices can be reduced through an innovative approach to the design and manufacturing process, but governments could also work to introduce subsidies for certain devices if they’re to be applied in a certain way. For instance, 3D printers at their very core “make things,” and could be the missing link for a budding entrepreneur to bring an idea to life. Lessening the barrier to such products could go a long way in increasing access.

ADVICE TO THE YOUNG ENGINEERS

GN: Please give advice and words of wisdom about the campaign for using these technologies to improve lives to our young global audience.

Armani: The current state of global connectedness not only gives young innovators access to experts—such as freelancers—who can help them realize proof of concept of their dreams affordably, it also gives them a platform where they can test the validity of their ideas, even make them go viral within a niche. In fact, today’s innovations seem to start at the individual and small company level, and then snapped up by larger companies. There has never been a better time to pursue a new idea because the barrier to entry is less than ever before. We expect to see less billionaires, but more millionaires, in the coming decades with big ideas.